Services for the improvement of the productive and industrial process

An adequate and sustainable use of resources and industrial processes is a differentiating element for companies

Tools such as quality, the environment, innovation… Management Systems correctly handled and implemented, allow companies to consolidate their processes and move forward through continuous improvement.

The automatisation, digitalisation and optimisation of industrial processes is a critical necessity, which all companies that aspire to remain in the market must address.

AIJU has a long history and experience in providing companies with advice on how to efficiently implement all these work tools and systems in a way that adjusts to the needs of each organisation.

Services for the improvement of the productive and industrial processes

- Quality Management Systems ISO 9001

- Quality Management Systems in the Automotive Sector IATF

- Legal requirements for companies within the food chain: advice on how to obtain and retain the Industrial Health Register (“RSI”)

- “IFS PAC secure” – Quality and Safety Standard for Packaging Materials

- IFS – Food Quality and Safety Standard for Food Products

- UNE -EN ISO 22000

- Product Conformity Declarations.

Contact person: Enrique Gramaje calidad@aiju.es

- Advice on how to fund and develop R&D&I projects.

- Advice on how to manage and develop projects.

- Technological Surveillance, industrial property management.

Contact person: David Monllor futurebusiness@aiju.es

- Diagnosis of innovation and strategic plans and corporate innovation.

- R&D&I management systems (UNE 166002), and project management systems.

Contact person: Ana León ingenieria@aiju.es

- Differentiate your productive process and your product from those of the competition by improving your environmental performance.

- Save on the use of resources (raw materials, water, energy…).

- Make sure you are in compliance with all environmental legislation requirements (waste, wastewater, atmospheric emissions, packaging, acoustics, soils, legionella…).

- Minimise the cost of environmental management (expenditure on waste management, payment of taxes such as sanitation fees and recycling centres for packaging materials…).

- Implement an environmental management system.

- Take advantage of environmental marketing tools (eco-labelling) and profit from the global trends in R&D&I(Circular Economy, Zero Waste, alternative wastewater treatment…) to define your strategy to improve your position in the market.

Contact person: Enrique Añó enriqueanyo@aiju.es

- Design and development of electronics for products and equipment.

- Intelligent functional coatings.

Contact person: Rubén Beneito energia@aiju.es

- Logistics 4.0: Web management and cloud computing.

- Development of cloud systems, IoT.

- Sensorics in the manufacturing process.

- Data analysis.

- Integration of new technologies into the manufacturing process.

- Development of safe training systems through immersive environments.

- Integration of Augmented Reality systems to obtain real-time information about manufacturing processes.

Contact person: Cesar Carrión ccarrion@aiju.es

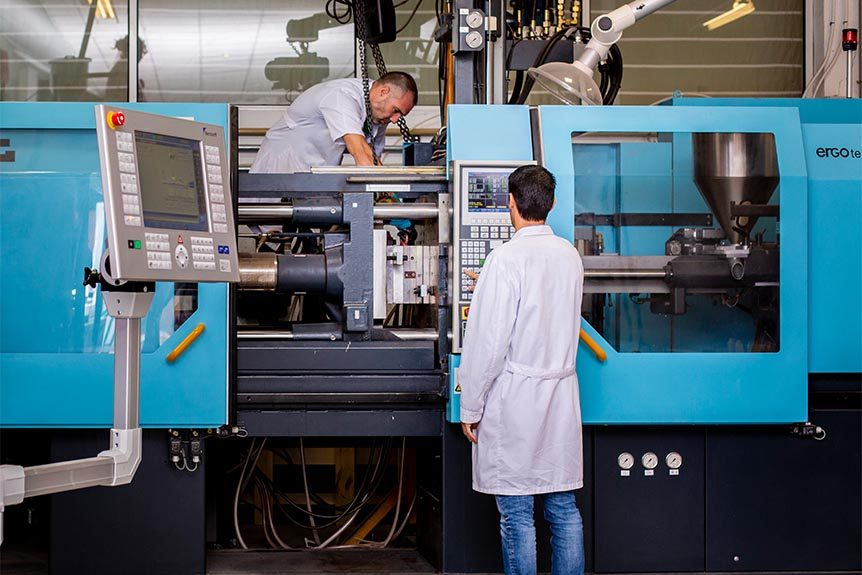

- Injection moulding troubleshooting.

- Conformal cooling.

- Moulding tests services (injection moulding, blow moulding, thermoforming, rotational moulding, extrusion-blow moulding…).

- Metrology.

Read more

Contact person: Miguel Ángel León miguelangelleon@aiju.es

- Acquisition of specific skills in order to work with highly demanding sectors such as the automotive industry, food and health packaging…

- Ability to adapt to change, continuously innovating in all the company’s manufacturing, organisational and management processes.

- Continuous improvement and standardisation of corporate and industrial processes, obtaining a high degree of efficiency.

- Energy-sustainable and environmentally friendly manufacturing processes.

- Generating a higher efficiency. The objective of companies that have a QMS is to maximize the efficiency and quality of their processes.

- Improved management process. Managers can systematise the acquisition of relevant information, and based on data use a monitoring and analysis system take the necessary decisions for their business.

- Increase employee motivation. Clear and defined functions, established capacitation systems, as well as a clear understanding of how their roles affect the sustainability of the business

- Increase the level of satisfaction of your clients. Establishing a framework to monitor and periodically revise the needs of your clients is key to sustaining your business in a global and competitive market.

- Digitalisation of your company and processes as a crucial action to maintain a growth model that allows you to increase your productivity, efficiency.

- Process optimisation and solving processing problems, in order to reduce costs and increase the competitivity of your company. This can be achieved by integrating cooling systems, systems that analyse and correct defects in moulded parts, processing tests with different technologies, the dimensional metrology of parts and tools, or by applying surface treatments for your pieces.

Our proximity and knowledge of the reality of the region’s industrial ecosystem allows us to quickly assess and diagnose companies’ needs and future plans, proposing possible solutions or actions that allow a greater guarantee of success. Actions designed and executed by professionals with lengthy track records and considerable experience.

Our team has over 20 years of experience providing support in many fields of industrial organisation and management, the improvement of manufacturing processes, process automatisation and digitalisation, the environment and energy efficiency.

In parallel, our projects office supports the management of corporate R&D&I projects. We can also help you to increase your company’s presence and participation in forums and networks at the national and international level, in order to seek out more opportunities and define new R&D&I business lines. It is worth noting that AIJU is the national contact point for the PIDI network of the CDTI.

We in AIJU are pioneers in the implementation of certain management systems based on different standards; we have never been afraid to tackle new challenges. That has allowed us to give advice to many companies on how to implement and maintain their quality management systems, environmental management systems, innovation management, etc…

- More than 25 years advising companies on ISO 9001 systems (toys, furniture, plastics, metal, moulds…).

- More than 20 years advising companies on ISO 14001 systems, as well as providing technical and environmental legal advice.

- More than 10 years advising companies on how to obtain health registration (food packaging).

- More than 10 years advising companies on BRC systems or ISO 22000 (food packaging). Pioneers with the first certified companies in the sector.

- More than 15 years advising companies on TS or IATF 16949.

- We advised the first company ever to obtain ISO 166002 certification in the plastics sector in the Community of Valencia.

- More than 5 years advising companies on process automatisation, designing unique custom projects.

- More than 5 years advising companies on corporate digitalisation, continuously achieving state-of-the-art levels in sensorics, cloud systems, IoT, Big Data, etc.).

- More than 20 years optimising industrial processes in order to minimise production costs.

- And more than 25 years advising companies on how to obtain funding for their R&D&I projects.